Choosing the right industrial steel doors is a critical decision for any business that aims to enhance security, efficiency, and aesthetic appeal in its facilities. These doors serve as a vital component in protecting assets, ensuring safety, and facilitating smooth operations within an industrial environment. Given the wide variety of options available, selecting the most suitable industrial steel doors can be overwhelming. Factors such as durability, insulation, fire resistance, and operational efficiency must all be taken into account to make an informed choice.

In this guide, we will delve into ten essential tips that can significantly aid in your decision-making process. From understanding the specific requirements of your facility to evaluating the door materials and design options, each tip will provide valuable insights to help narrow down your choices. Additionally, considering the functional aspects, such as the frequency of use and environmental impact, will further guide you in selecting industrial steel doors that not only meet your operational needs but also contribute to the overall safety and functionality of your premises. As we explore these tips, the goal is to equip you with the knowledge necessary to make a confident and informed choice in your investment.

When selecting the right industrial steel doors, it's essential to understand the different types available in the market. The primary categories include hollow metal doors, insulated doors, fire-rated doors, and reinforced doors.

Hollow metal doors are favored for their durability and security, and according to the Steel Door Institute, they can withstand significant impacts while providing excellent resistance to corrosion. Insulated doors are optimal for facilities requiring temperature control, as they can reduce energy costs by maintaining internal climate conditions. Fire-rated doors, on the other hand, are crucial for safety, as they help contain fires and protect exit routes.

When choosing industrial steel doors, consider the specific needs of your facility. Tip one: assess the security requirements. High-traffic areas may demand doors with enhanced security features, while quieter zones might prioritize sound insulation. Tip two: evaluate environmental factors. For instances with extreme weather conditions, select doors with appropriate insulation ratings and materials designed to withstand such climates. Tip three: prioritize compliance with local codes and regulations, especially for fire-rated doors, as these must adhere to specific safety standards to ensure the protection of life and property.

By factoring in these components, you can make a more informed decision that aligns with your operational needs and ensures the longevity and effectiveness of the doors chosen for your industrial space.

When choosing the right industrial steel doors, one of the key aspects to consider is their strength and durability. Steel doors are often subjected to harsh environments, making it essential to evaluate their ability to withstand wear and tear over time. Look for doors made from high-grade stainless or galvanized steel, as these materials offer superior resistance to corrosion and physical damage. Additionally, check for thickness specifications, as thicker steel generally provides better protection against impacts and intrusions.

Consider the door's construction and design elements that can enhance its durability. For instance, a solid core, reinforced frames, and heavy-duty hinges can significantly improve the door's overall strength. Another important tip is to assess the door's thermal performance. Insulated steel doors can help maintain a controlled indoor climate, reducing energy costs while also enhancing the door’s longevity.

Additionally, do not overlook the importance of proper installation. Ensuring that a steel door is installed correctly can greatly influence its durability. Consult with professionals to understand the best practices for installation and maintenance.

Regular inspections can also help identify potential vulnerabilities before they become significant issues, ultimately preserving the door's functionality and lifespan.

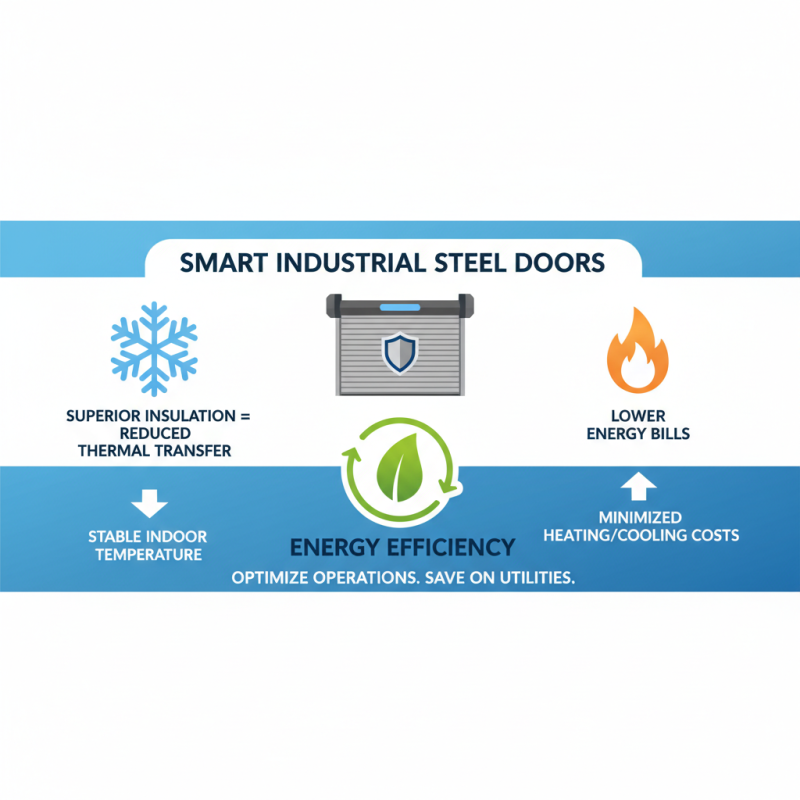

When selecting industrial steel doors, insulation and energy efficiency features should be at the forefront of your decision-making process. Superior insulation can significantly influence the overall energy consumption of your facility. These doors are designed with materials that reduce thermal transfer, helping to maintain a stable indoor temperature. As a result, businesses can minimize heating and cooling costs, which is especially important in environments where temperature control is vital for operations or storage.

Additionally, it's essential to consider the door's sealing mechanisms and construction quality. High-performance steel doors often feature advanced weather stripping and tight-fitting designs that prevent air leaks. This enhances their insulative properties and contributes to improved energy performance. Evaluating the R-value, which measures thermal resistance, can also help in identifying the most energy-efficient options. A higher R-value indicates better insulation, so it’s worth investing time in understanding how different doors compare in this regard. Prioritizing these insulation and energy efficiency aspects not only supports sustainability goals but also translates into long-term cost savings for your facility.

When selecting industrial steel doors, assessing their security features is paramount to ensuring the safety and integrity of your facility. One critical aspect to consider is the door's material strength. Heavy-duty steel construction typically provides enhanced durability against forced entry attempts. Additionally, look for doors that incorporate reinforcement features, such as internal steel reinforcements or additional locking mechanisms, which can further deter unauthorized access.

Another key element to evaluate is the locking system employed in the doors. High-security locks, such as deadbolts or multi-point locking systems, offer superior protection compared to standard locks. Moreover, consider options that allow for restricted key control or electronic access systems that can track entry and exit, fostering tracking capabilities with a record of access patterns. With various vulnerabilities affecting industrial spaces, prioritizing these security features will help create a safer environment for your operations.

When selecting industrial steel doors, one of the most crucial aspects is identifying the right size and configuration for your space. Measuring the entryway accurately is essential to ensure that the doors fit seamlessly. Begin by evaluating the height and width of the opening, taking note of any obstructions such as pipes, lighting, or uneven floors that could affect the installation. It is also important to consider the door's swing direction and space required for operation. A comprehensive assessment will prevent complications during installation and operation.

Beyond basic measurements, understanding the specific requirements of your space can further refine your selection. Consider factors such as the intended use of the door, foot traffic frequency, and environmental conditions within the facility. For example, heavy-duty doors may be necessary for high-traffic areas, while insulated options might be better suited for temperature-sensitive environments. Additionally, configurations such as bi-fold or sliding doors can maximize space efficiency, which is particularly valuable in tight working areas. Taking these factors into account will help ensure that you choose industrial steel doors that are not only functional but also enhance the overall workflow of your operation.